How an Ultra-Pure RO Water Machine Works?

It is well known in the hemodialysis field that the water used in hemodialysis treatment is not ordinary drinking water, but must be reverse osmosis (RO) water that meets the stringent standards of AAMI. Every dialysis center requires a dedicated water purification plant to produce the essential RO water, ensuring that the water output matches the consumption needs of the dialysis equipment. Typically, each dialysis machine requires approximately 50 liters of RO water per hour. Over the dialysis treatment of one year, a single patient will be exposed to 15,000 to 30,000 liters of RO water, implying the RO water machine plays a critical role in kidney disease therapy.

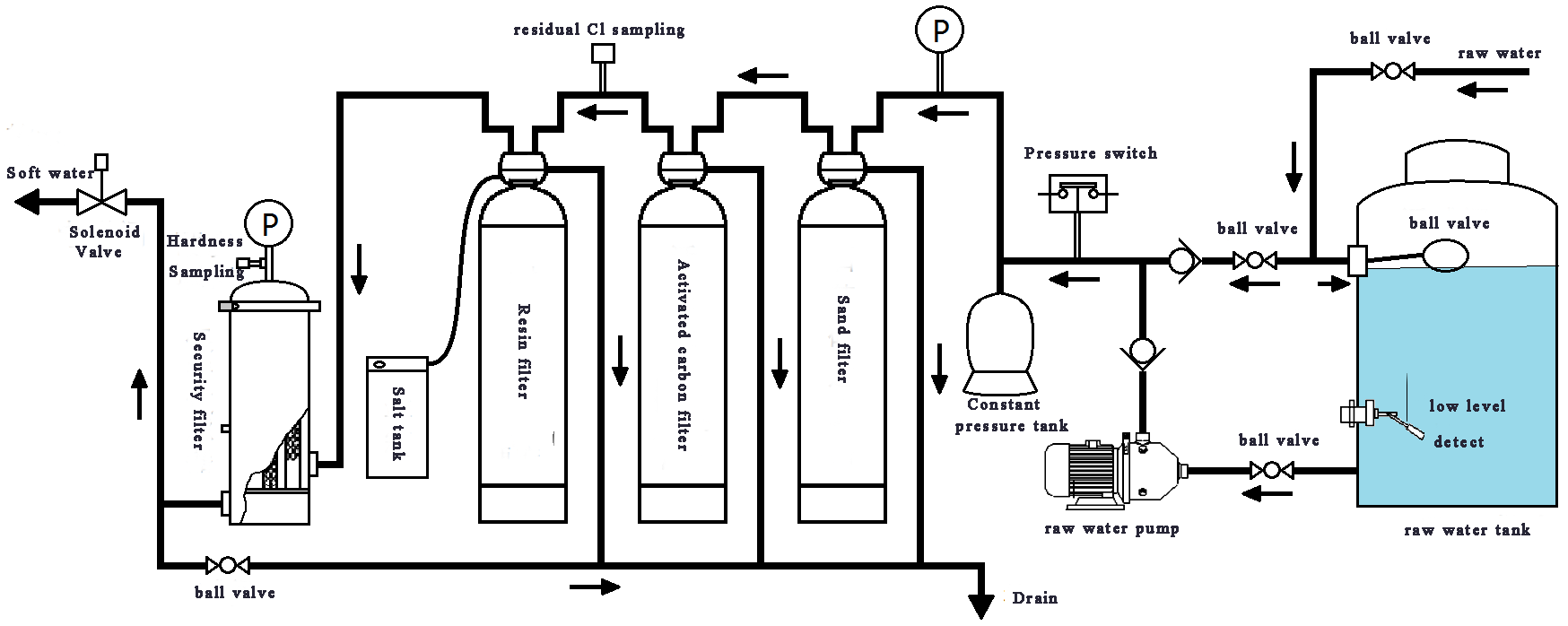

The structure of the RO water plant

A dialysis water purification system generally includes two main phases: the pre-treatment unit and the reverse osmosis unit.

Pre-Treatment System

The pre-treatment system is designed to remove impurities such as suspended solids, colloids, organic matter, and microorganisms from the water. This step is crucial for ensuring the functioning of the reverse osmosis membrane in the subsequent phase and extends its service life. The pre-treatment unit of the RO water machine manufactured by Chengdu Wesley consists of a quartz sand filter, a carbon adsorption tank, a resin tank with a brine tank, and a precision filter. The quantity and installation sequence of these tanks can be adjusted based on the raw water quality in different countries and regions. This part works with a constant pressure tank to maintain stable pressure and water flow.

Reverse Osmosis System

The reverse osmosis system is the heart of the water treatment process that utilizes membrane separation technology to purify the water. Under pressure, water molecules are forced to the pure water side, while impurities and bacteria are intercepted by the reverse osmosis membrane and retained on the concentrated water side being discharged as waste. In Wesley’s RO purification system, the first stage of reverse osmosis can remove over 98% of dissolved solids, more than 99% of organic matter and colloids, and 100% of bacteria. Wesley’s innovative triple-pass reverse osmosis system produces ultra-pure dialysis water, which exceeds the U.S. AAMI dialysis water standard and U.S. ASAIO dialysis water requirement, with clinical feedback indicating that it significantly enhances patient comfort during therapy.

During the purification, the recovery rate of concentrated water in the first stage is more than 85%. The concentrated water produced by the second and third stages is 100% recycled, which enters the balancer and dilutes the filtered water, reducing the concentration of the filtered water, which is conducive to further improving the RO water quality and prolonging the service life of the membrane.

Performance and Features

Wesley RO water machines are equipped with high-quality components, including original imported Dow membranes and sanitary-grade stainless steel 316L for the main pipe fitting and valves. The internal surfaces of the pipelines are smooth, eliminating dead zones and corners that could avoid bacteria breeding. For the second and third stages of reverse osmosis, the direct supply mode is used between all levels of membrane groups, with an automatic flushing function during standby periods to further guarantee the safety of water quality.

The fully automated operation system, with a custom auto on/off function, employs a high-performance programmable logic controller(PLC) and humanization computer interface, allowing one key to start the water production and disinfection program. The machine supports various water production modes, including single-pass and double-pass combinations. In emergencies, the water-producing mode can be switched between single-pass and double-pass to ensure a continuous water supply of dialysis, allowing for maintenance without water cut-off.

Comprehensive Safety Protection System

Wesley RO water purification system comes with a robust safety protection system, including conductivity monitors, raw water protection, first and second-stage lake of water protection, high or low-pressure protection, power protection, and self-lock devices. If any parameters are detected as abnormal, the system will automatically shut down and restart. Additionally, once a water leak occurs, the machine will automatically cut off the water supply to secure the safety of equipment operation.

Customization and Flexibility

Wesley also offers powerful optional features, including UV sterilizer, hot disinfection, online remote monitoring, mobile app function, etc. The plant capacity ranges from 90 liters to 2500 liters per hour, fully accommodating the needs of dialysis centers. The capacity of 90L/H model is a portable RO water machine, a compact and mobile unit with a double pass RO process that can support two dialysis machines, making it an ideal choice for smaller facilities.

Chengdu Wesley Bioscience Technology Co., as a leading manufacturer of hemodialysis equipment in China and the only company that can provide one-stop solutions in blood purification, is committed to improving the comfort and effect of renal dialysis for kidney failure patients and enhancing quality of service for our cooperators. We will consistently pursue advanced technology and perfect products and create a world-class hemodialysis brand.

Post time: Jan-14-2025